Shape Morphing Domes

I spent the summer of 2025 at Imperial College London, working in the MaXtaloy Group in the Department of Materials.

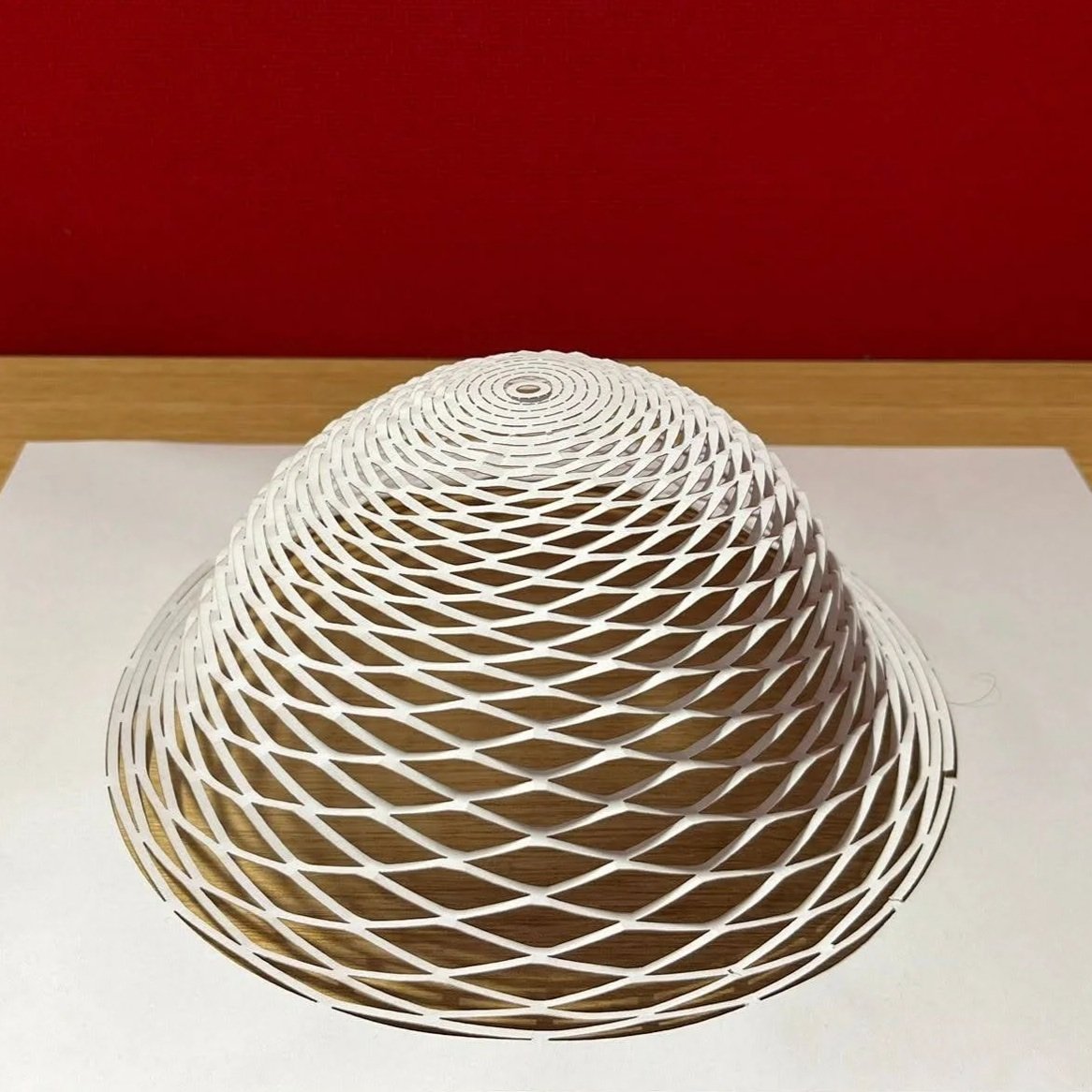

My goal was to create an environmentally sensitive structure that changes shape with response to an external cue. I was particularly interested in starting from a flat sheet, and creating height.

The hope is to scale these structures, and utilize their minimal profile state prior to deployment as a means of creating habitable structures in extreme environments.

Material Choice

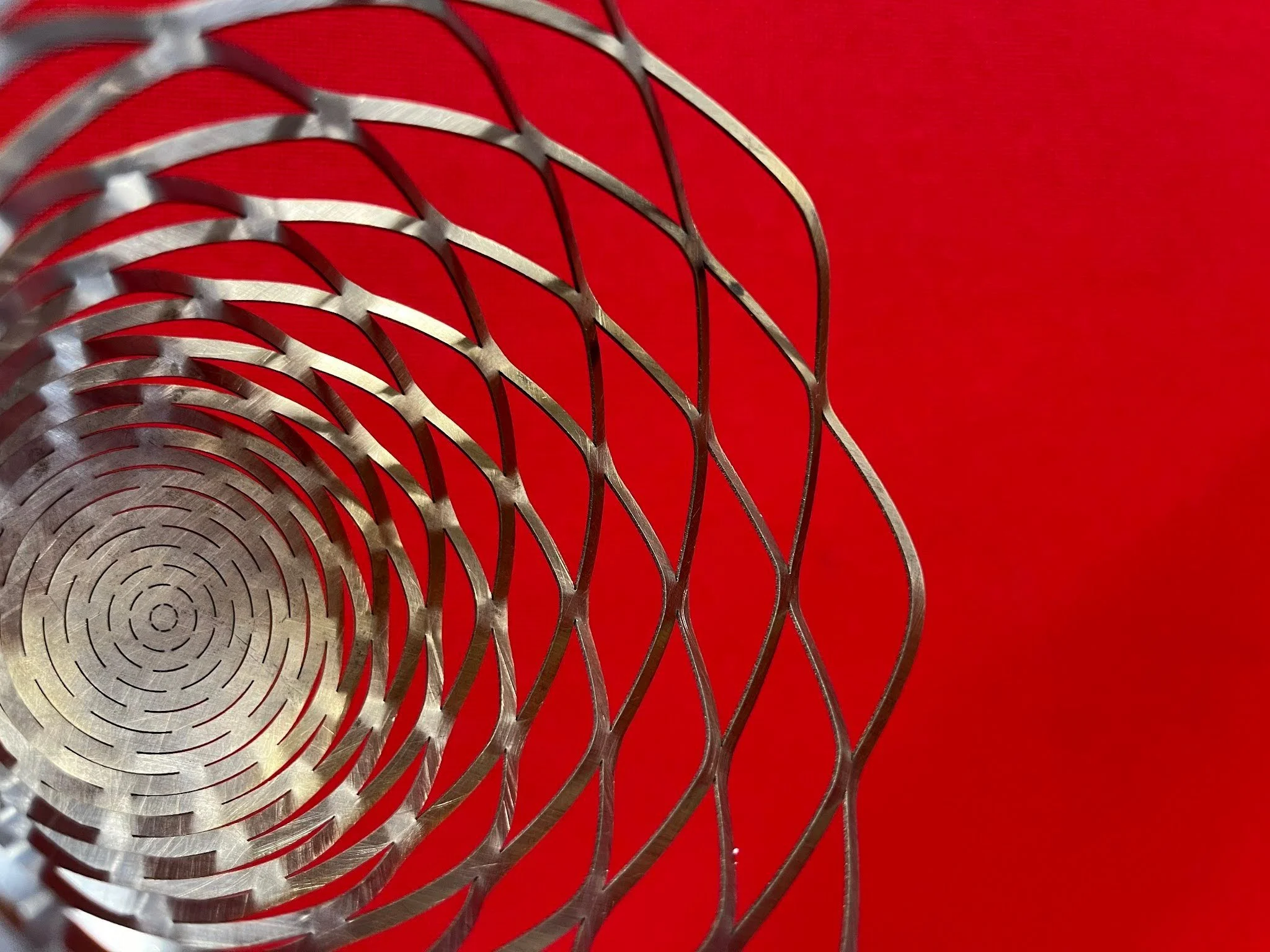

Nitinol is an alloy of approximately 50/50 nickel and titanium, as seen by the green region in the binary phase diagram. Nitinol has specific material characteristics that lend well to this project, namely its shape memory properties. This allows nitinol to “remember” a configuration, such that a user can deform the material and use heat to trigger a transformation back to its original shape. Nitinol also exhibits superelasticity, has significant kink resistance, and is biocompatible (hence applications in stents and other medical devices).

Design

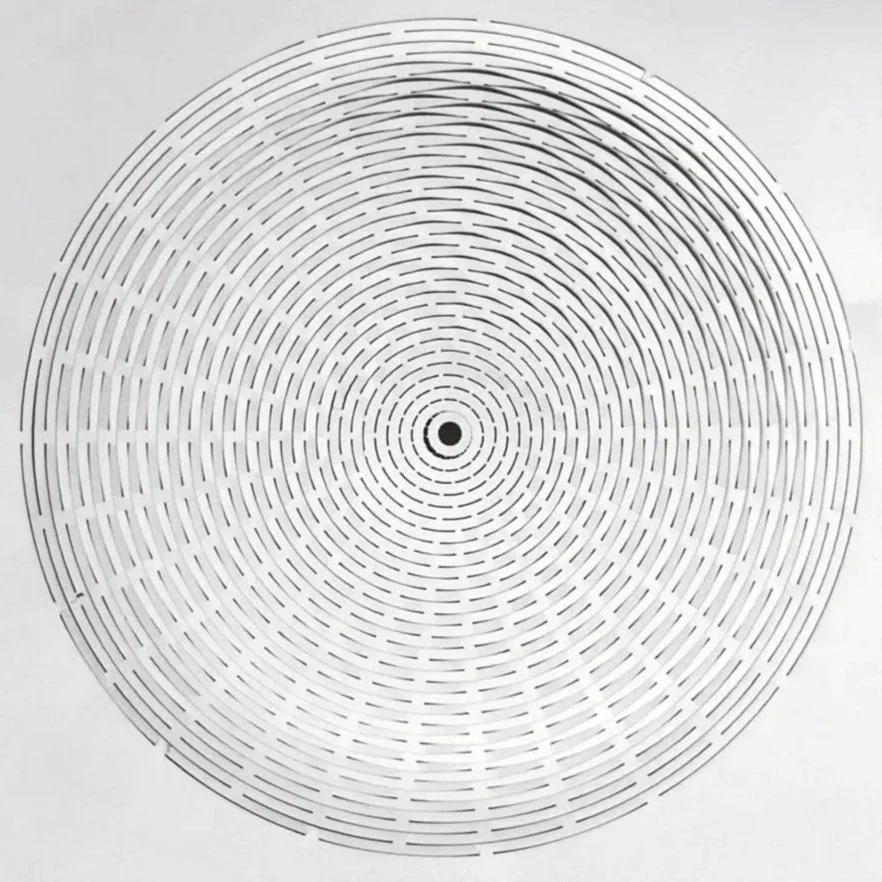

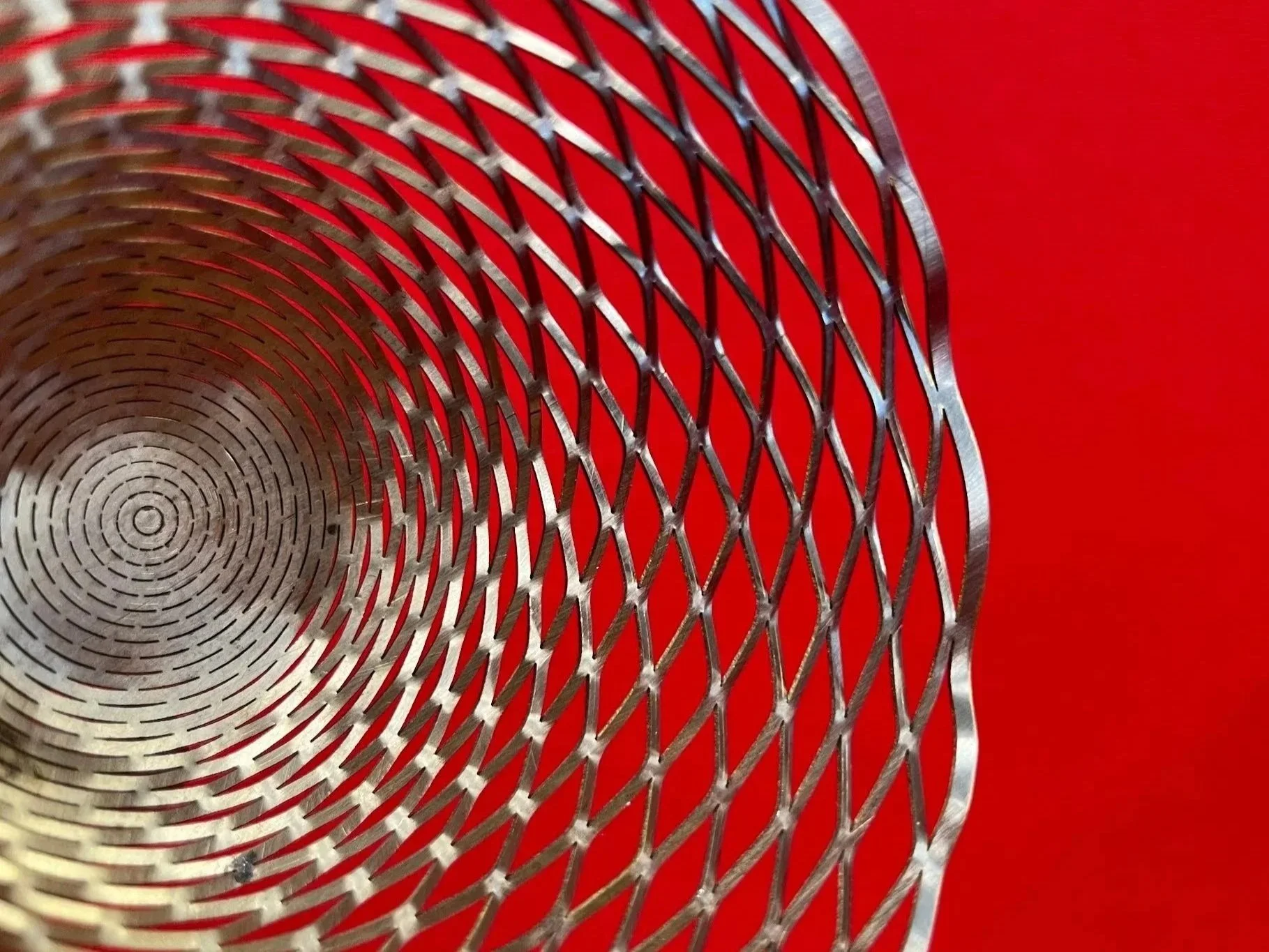

I created the designs through Grasshopper in Rhino, allowing me to easily change parameters and generate new variations. With the many materials I prototyped with (paper, card, stainless steel, aluminum and nitinol) I focused on the main attributes that change the ease of deploying the structures (i.e, the pressure required to deform into a dome). Three attributes control this factor: number of rings, the number of divisions of each ring, and the length of each arc division.

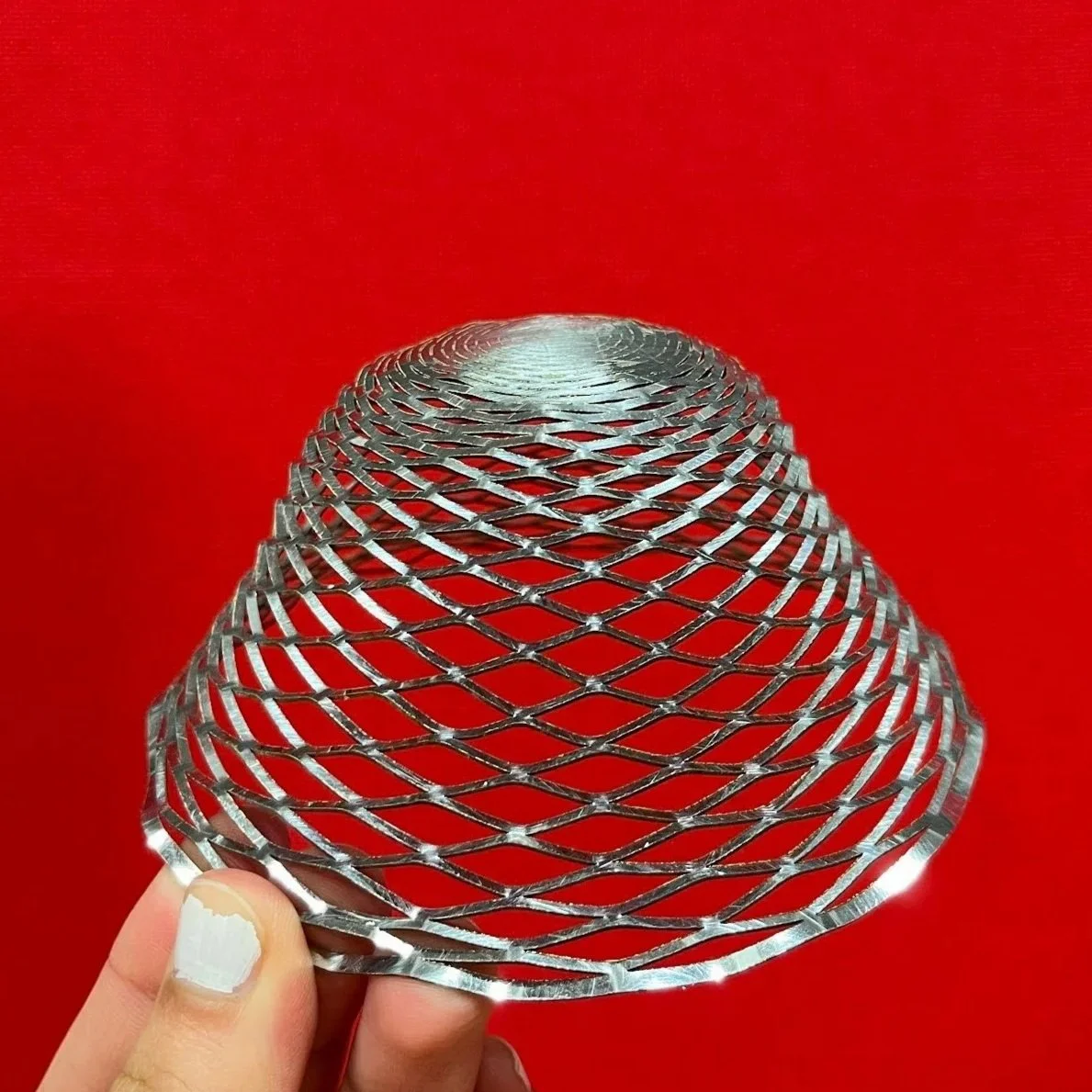

Given the superelasticity of nitinol, and the thickness of the sheet provided, the nitinol design was chosen to have high ring number, low division number and high arc length. This makes each “segment” of the dome thin and long, and consequently easy to deform.

Prototyping

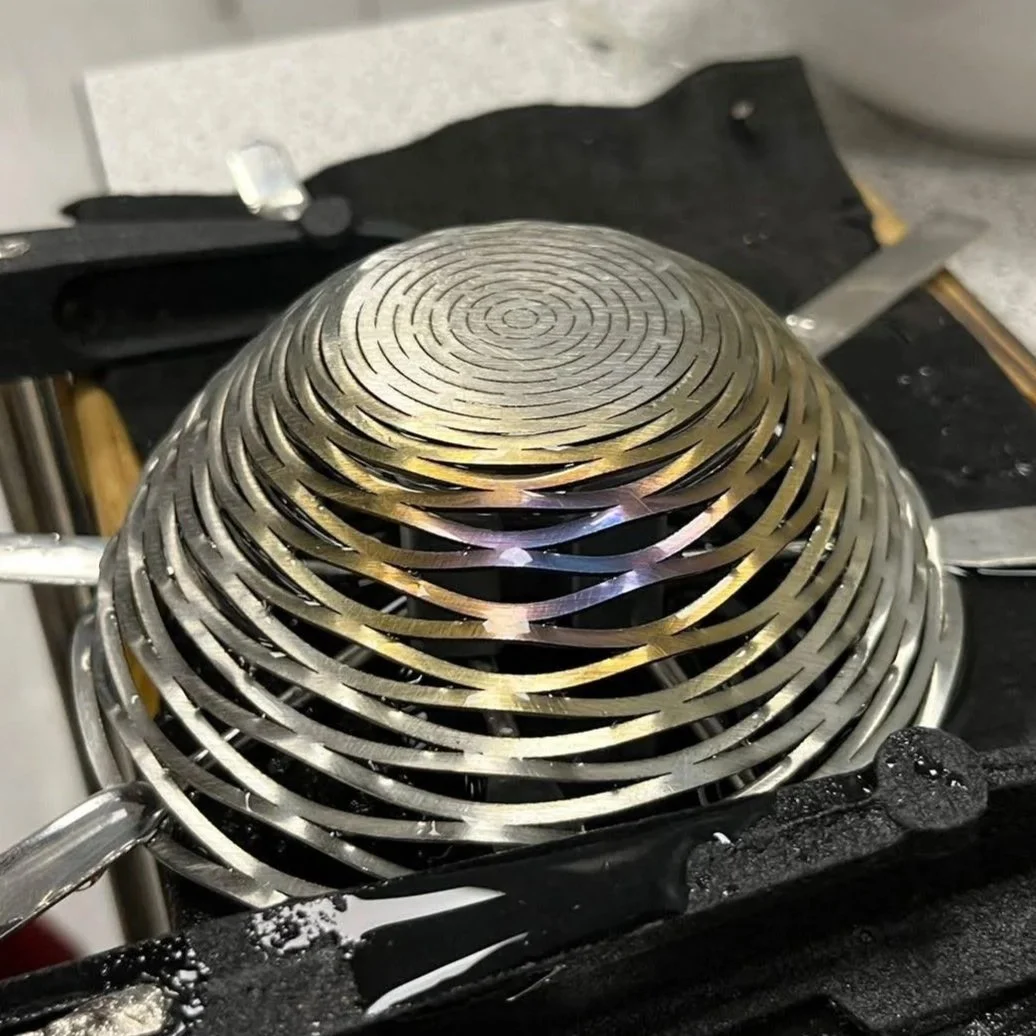

I prototyped the domes out of card, stainless steel and aluminum. The cuts were made using a universal laser cutter and a Rofin laser cutter. I also CNC milled an aluminum model, but ultimately decided against that manufacturing method because of the endmill’s role in removing material and limiting the dimensions of the dome segments.

Challenges: Because nitinol only retains its shape memory properties at a narrow composition range, I had to ensure that my manufacturing methods did not vaporize too much nickel and alter the properties of the material. I test cut strips of Nitinol on the Rofin, before optimizing the Nitinol design, and moving on to heat training.

Number of Rings

Length of Divisions

Number of Divisons

Training

Manually deforming the sheet into a dome and then heating it causes it to collapse. To train it to rise when heated, the dome must be deformed and braced, then heated over its phase transition temperature into the austenite phase, before being quenched. The quenched structure can then be manually flattened into a sheet and heated again to rise into the dome.

Challenges: I tried multiple methods of bracing the dome during the training process, but Nintinol’s superelasticity makes it difficult to plastically deform manually. The dome ripped out u-nails in my first training attempt, but bracing with an X-rail and spatulas worked better. However, the training still lacked uniformity (as seen in the dome deployment videos by the uneven rising).

Grasshopper Code

Allows for parametric adjustment and rapid prototyping